MODEL NO. 36 REDIN "WASH & GRIND" GEAR DEBURRING/BRUSHING MACHINE

SERIAL NO. 36-36 (NEW 1998)

SUITABLE FOR THE AUTOMATIC DEBURRING/BRUSHING OF SPUR AND

HELICAL GEARS, STRAIGHT AND SPIRAL BEVEL GEARS, SPROCKETS,

WORM-GEARS, AND SIMILAR WORK-PIECES UP TO 20" (508MM) DIAMETER

AND 6" (152MM) FACE

BASIC MACHINE CONFIGURATION / WITH AUTO CYCLE

MACHINE SPECIALLY CONFIGURED TO ALLOW WORK-PIECE TO BE LOADED THROUGH A “ROOF-HATCH” VIA OVERHEAD GANTRY-CRANE. WHILE ON AUTOMATIC, THE “START” BUTTON AND THE

“SECOND-HAND” BUTTON ARE PUSHED SIMULTANEOUSLY UNTIL THE PNEUMATICALLY POWERED FRONT DOORS ARE CLOSED AND THE

DEBURRING CYCLE HAS STARTED. THE WORK-TABLE WITH THE

WORK-PIECE IS ROTATED CLOCKWISE FOR TWO REVOLUTIONS WHILE IT IS

BEING DEBURRED. THE “SKIVE-BRUSH” UNIT IS ALSO ROTATING CLOCKWISE AT THIS TIME. THE “UPPER” DEBURRING TOOL WITH AIR-POWERED MOTOR, AND THE “LOWER” SKIVE-TOOL WITH AIR-POWER MOTOR ARE ALSO OPERATING AT THIS TIME, WITH COOLANT BEING PUMPED ONTO THE WORK-PIECE AND SKIVE BRUSH STATION/UNIT.

THE ROTATION OF THE WORK-SPINDLE AND WORK-PIECE IS THEN REVERSED (TO COUNTER-CLOCKWISE) FOR TWO REVOLUTIONS. THE SKIVE-BRUSH ROTATION IS ALSO REVERSED. DURING THE COUNTER-CLOCKWISE ROTATION,

THE LOWER DEBURRING MOTOR ON THE RIGHT SIDE OF THE MACHINE IS IN OPERATION. COOLANT IS PUMPED ONTO THE PART AND THE SKIVE-BRUSH DURING THE FIRST COUNTER-CLOCKWISE REVOLUTION. DURING THE SECOND

COUNTER-CLOCKWISE REVOLUTION, THE COOLANT IS SWITCHED OFF, AND DRYING AIR IS SPRAYED ONTO THE GEAR PART.

EQUIPMENT / FEATURES:

FULL MACHINE ENCLOSURE WITH FACILITY FOR DUST EXHAUST AND

PNEUMATICALLY OPERATED FRONTAL GUARD DOOR, W/SUBSEQUENT

PNEUMATIC SYSTEM MANIFOLDS, AND COOLANT FILTRATION SYSTEM

ROTATING WORK-SPINDLE WITH PART FIXTURE

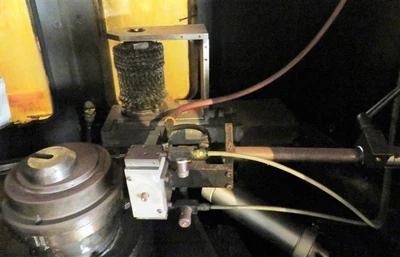

3-SPINDLE STATION ARRANGEMENT CONSISTING OF

(1) RIGHT-HAND UPPER AIR-DRIVEN MOTORIZED CARBIDE GRINDING CUTTER

WITH ADJUSTABLE BRACKET & STAND

(1) LEFT-HAND LOWER AIR-DRIVEN MOTORIZED CARBIDE GRINDING CUTTER

WITH ADJUSTABLE BRACKET & STAND

(1) RIGHT-REAR MOUNTED PIVOT SKIVE BRUSH ASSEMBLY EMPLOYING

STACKED SERIES OF WEILER 6” DIAMETER WIRE BRUSHES

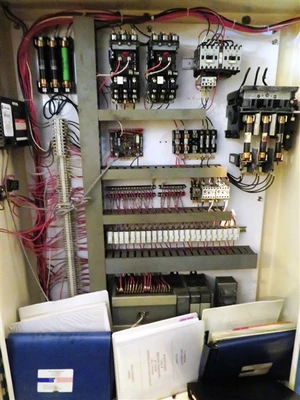

ALLEN BRADLEY PLC CONTROL WITH RS-LOGIX 500 SOFTWARE

AND 550 ALLEN BRADLEY “PANEL-VIEW” CONTROL PANEL

COMPLETE PNEUMATICS WITH LINES, FLOW-CONTROL VALVES, SOLENOIDS, GAUGES, ETC.

FULL COMPLEMENT OF ELECTRICS (MOTORS/CONTROLS)

(PRESENTLY ARRANGED FOR 480 VOLT, 60HZ OPERATION)

FULL MACHINE DOCUMENTATION FOR MACHINE & CONTROLLER, WITH MACHINE

DRAWINGS FOR PNEUMATIC, AND ELECTRICAL SYSTEM, PARTS LIST, ETC.

MODEL NO. 36 REDIN "WASH & GRIND" GEAR DEBURRING/BRUSHING MACHINE

SERIAL NO. 36-36 (NEW 1998)

SUITABLE FOR THE AUTOMATIC DEBURRING/BRUSHING OF SPUR AND

HELICAL GEARS, STRAIGHT AND SPIRAL BEVEL GEARS, SPROCKETS,

WORM-GEARS, AND SIMILAR WORK-PIECES UP TO 20" (508MM) DIAMETER

AND 6" (152MM) FACE

BASIC MACHINE CONFIGURATION / WITH AUTO CYCLE

MACHINE SPECIALLY CONFIGURED TO ALLOW WORK-PIECE TO BE LOADED THROUGH A “ROOF-HATCH” VIA OVERHEAD GANTRY-CRANE. WHILE ON AUTOMATIC, THE “START” BUTTON AND THE

“SECOND-HAND” BUTTON ARE PUSHED SIMULTANEOUSLY UNTIL THE PNEUMATICALLY POWERED FRONT DOORS ARE CLOSED AND THE

DEBURRING CYCLE HAS STARTED. THE WORK-TABLE WITH THE

WORK-PIECE IS ROTATED CLOCKWISE FOR TWO REVOLUTIONS WHILE IT IS

BEING DEBURRED. THE “SKIVE-BRUSH” UNIT IS ALSO ROTATING CLOCKWISE AT THIS TIME. THE “UPPER” DEBURRING TOOL WITH AIR-POWERED MOTOR, AND THE “LOWER” SKIVE-TOOL WITH AIR-POWER MOTOR ARE ALSO OPERATING AT THIS TIME, WITH COOLANT BEING PUMPED ONTO THE WORK-PIECE AND SKIVE BRUSH STATION/UNIT.

THE ROTATION OF THE WORK-SPINDLE AND WORK-PIECE IS THEN REVERSED (TO COUNTER-CLOCKWISE) FOR TWO REVOLUTIONS. THE SKIVE-BRUSH ROTATION IS ALSO REVERSED. DURING THE COUNTER-CLOCKWISE ROTATION,

THE LOWER DEBURRING MOTOR ON THE RIGHT SIDE OF THE MACHINE IS IN OPERATION. COOLANT IS PUMPED ONTO THE PART AND THE SKIVE-BRUSH DURING THE FIRST COUNTER-CLOCKWISE REVOLUTION. DURING THE SECOND

COUNTER-CLOCKWISE REVOLUTION, THE COOLANT IS SWITCHED OFF, AND DRYING AIR IS SPRAYED ONTO THE GEAR PART.

EQUIPMENT / FEATURES:

FULL MACHINE ENCLOSURE WITH FACILITY FOR DUST EXHAUST AND

PNEUMATICALLY OPERATED FRONTAL GUARD DOOR, W/SUBSEQUENT

PNEUMATIC SYSTEM MANIFOLDS, AND COOLANT FILTRATION SYSTEM

ROTATING WORK-SPINDLE WITH PART FIXTURE

3-SPINDLE STATION ARRANGEMENT CONSISTING OF

(1) RIGHT-HAND UPPER AIR-DRIVEN MOTORIZED CARBIDE GRINDING CUTTER

WITH ADJUSTABLE BRACKET & STAND

(1) LEFT-HAND LOWER AIR-DRIVEN MOTORIZED CARBIDE GRINDING CUTTER

WITH ADJUSTABLE BRACKET & STAND

(1) RIGHT-REAR MOUNTED PIVOT SKIVE BRUSH ASSEMBLY EMPLOYING

STACKED SERIES OF WEILER 6” DIAMETER WIRE BRUSHES

ALLEN BRADLEY PLC CONTROL WITH RS-LOGIX 500 SOFTWARE

AND 550 ALLEN BRADLEY “PANEL-VIEW” CONTROL PANEL

COMPLETE PNEUMATICS WITH LINES, FLOW-CONTROL VALVES, SOLENOIDS, GAUGES, ETC.

FULL COMPLEMENT OF ELECTRICS (MOTORS/CONTROLS)

(PRESENTLY ARRANGED FOR 480 VOLT, 60HZ OPERATION)

FULL MACHINE DOCUMENTATION FOR MACHINE & CONTROLLER, WITH MACHINE

DRAWINGS FOR PNEUMATIC, AND ELECTRICAL SYSTEM, PARTS LIST, ETC.

PRINCIPAL SPECIFICATIONS:

( estimated )

Work table diameter 8” (203.2mm)

Maximum diameter work-piece (approx..) 20" (508mm)

Minimum O.D. 0" (0mm)

Maximum I.D. 18" (457.2mm)

Minimum I.D. 1.75” (44.45mm)

Maximum face width 6" (152.4mm)

Minimum D.P. 20 DP (1.27 module)

Maximum work-piece weight 500 Lbs. (227 kGs)

Grinding wheel speed 37,000 rpm

Work spindle speed 23 to 9.4 rpm

Overall machine length 118.25”(3,004mm)

Overall machine width 44” (1,118mm)

Overall machine height 71.5” (1,816mm)

Approx net weight 3,750 Lbs. (1,705 kGs)

NOTE: THIS MACHINE WAS BUILT SPECIFICALLY FOR A JOB AT

CATERPILLAR. IT WILL PROBABLY TAKE SOME MODIFICATIONS

TO DO YOUR SPECIFIC JOB. WE ARE NOT GOING TO RUN

THIS MACHINE.

PRICE: F.O.B. OUR WAREHOUSE

Work table diameter: 8” (203.2MM)

Maximum diameter work-piece (approx..): 20" (508MM)

Minimum o.d.: 0" (0MM)

Maximum i.d.: 18" (457.2MM)

Minimum i.d.: 1.75” (44.45MM)

Maximum face width: 6" (152.4MM)

Minimum d.p.: 20 DP (1.27 MODULE)

Maximum work-piece weight: 500 LBS. (227 KGS)

Grinding wheel speed: 37,000 RPM

Work spindle speed: 23 TO 9.4 RPM

Overall machine length: 118.25”(3,004MM)

Overall machine width: 44” (1,118MM)

Overall machine height: 71.5” (1,816MM)

Approx net weight 3,750 lbs.: (1,705 KGS)

We use cookies to improve your experience. Privacy Policy.