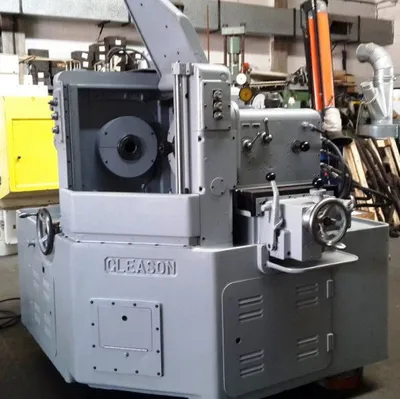

MODEL 119 GLEASON HYPOID SPIRAL BEVEL GEAR LAPPER

SERIAL NO. 608406

SUITABLE FOR THE LAPPING OF HARDENED HYPOID GEARS

AND PINIONS UP TO 17” (432MM) DIAMETER, OPERATING AT A

90-DEGREE SHAFT ANGLE

THE MACHINE IS BEING OFFERED IN FIRST CLASS CONDITION

THROUGHOUT AND HAVING BEEN PROFESSIONALLY REBUILT BY

GLEASON SERVICE SPECIALISTS.

EQUIPMENT / FEATURES:

AUTOMATIC LAPPING CYCLE

AUTOMATIC BACKLASH CONTROL

STANDARD SPLASH GUARD ARRANGEMENT

HYDRAULIC CHUCKING ATTACHMENT

DYNAMOMETER-TYPE BRAKE FOR LOAD SIMULATION

FULL COMPLEMENT OF ELECTRICS (MOTORS/CONTROLS)

To nose of pinion spindle (maximum): 10-1/2" (267MM)

To nose of pinion spindle (minimum): 6-1/4" (169MM)

To nose of gear spindle (maximum): 10-3/4" (273MM)

To nose of gear spindle (minimum): 5" (172MM)

Center of pinion spindle (maximum): 3" (76MM)

Diameter of gear (maximum nominal): 17" (432MM)

Diameter of gear (maximum actual w/extended guard: 22” (559MM)

Vertical: .040" (1.0MM)

Horizontal: .040" (1.0MM)

Backlash: .150" (3.8MM)

Diameter of spindle taper hole at large end: 3-29/32" (100MM)

Spindle taper per foot 39/64": (15MM)

Depth of spindle taper 6": (152MM)

Diameter of hole through spindle 3-1/2”: (89MM)

Hydraulic pump: 3/4 HP, 1800 RPM

Drive spindle speed: 600 & 1200 RPM

Main motor (two-speed): 2-1/2 HP, 900 RPM

Lapping compound pump motor: 1/2 HP, 1800 RPM

Oscillating drive motor: 1/15 HP, 0 TO 1725 RPM

Floor space: 64" X 90" (163X229CM)

Lapping guard closed: 59-1/2" (151CM)

Lapping guard open: 81-1/4" (206CM)

Net weight: 11,000 LBS (5000 KG)

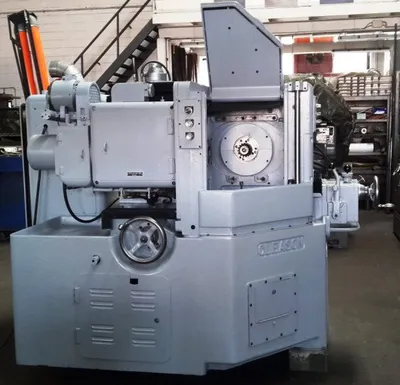

MODEL 119 GLEASON HYPOID SPIRAL BEVEL GEAR LAPPER

SERIAL NO. 608406

SUITABLE FOR THE LAPPING OF HARDENED HYPOID GEARS

AND PINIONS UP TO 17” (432MM) DIAMETER, OPERATING AT A

90-DEGREE SHAFT ANGLE

THE MACHINE IS BEING OFFERED IN FIRST CLASS CONDITION

THROUGHOUT AND HAVING BEEN PROFESSIONALLY REBUILT BY

GLEASON SERVICE SPECIALISTS.

EQUIPMENT / FEATURES:

AUTOMATIC LAPPING CYCLE

AUTOMATIC BACKLASH CONTROL

STANDARD SPLASH GUARD ARRANGEMENT

HYDRAULIC CHUCKING ATTACHMENT

DYNAMOMETER-TYPE BRAKE FOR LOAD SIMULATION

FULL COMPLEMENT OF ELECTRICS (MOTORS/CONTROLS)

To nose of pinion spindle (maximum): 10-1/2" (267MM)

To nose of pinion spindle (minimum): 6-1/4" (169MM)

To nose of gear spindle (maximum): 10-3/4" (273MM)

To nose of gear spindle (minimum): 5" (172MM)

Center of pinion spindle (maximum): 3" (76MM)

Diameter of gear (maximum nominal): 17" (432MM)

Diameter of gear (maximum actual w/extended guard: 22” (559MM)

Vertical: .040" (1.0MM)

Horizontal: .040" (1.0MM)

Backlash: .150" (3.8MM)

Diameter of spindle taper hole at large end: 3-29/32" (100MM)

Spindle taper per foot 39/64": (15MM)

Depth of spindle taper 6": (152MM)

Diameter of hole through spindle 3-1/2”: (89MM)

Hydraulic pump: 3/4 HP, 1800 RPM

Drive spindle speed: 600 & 1200 RPM

Main motor (two-speed): 2-1/2 HP, 900 RPM

Lapping compound pump motor: 1/2 HP, 1800 RPM

Oscillating drive motor: 1/15 HP, 0 TO 1725 RPM

Floor space: 64" X 90" (163X229CM)

Lapping guard closed: 59-1/2" (151CM)

Lapping guard open: 81-1/4" (206CM)

Net weight: 11,000 LBS (5000 KG)

We use cookies to improve your experience. Privacy Policy.